Can a change of solvent in the printer improve SMT printing?

ANY ENGINEER WILL TESTIFY lab testing may not correlate with field results. Laboratory data are developed under ideal conditions to generate accurate and repeatable data, whereas a production setting introduces variables not reproducible in the lab environment.

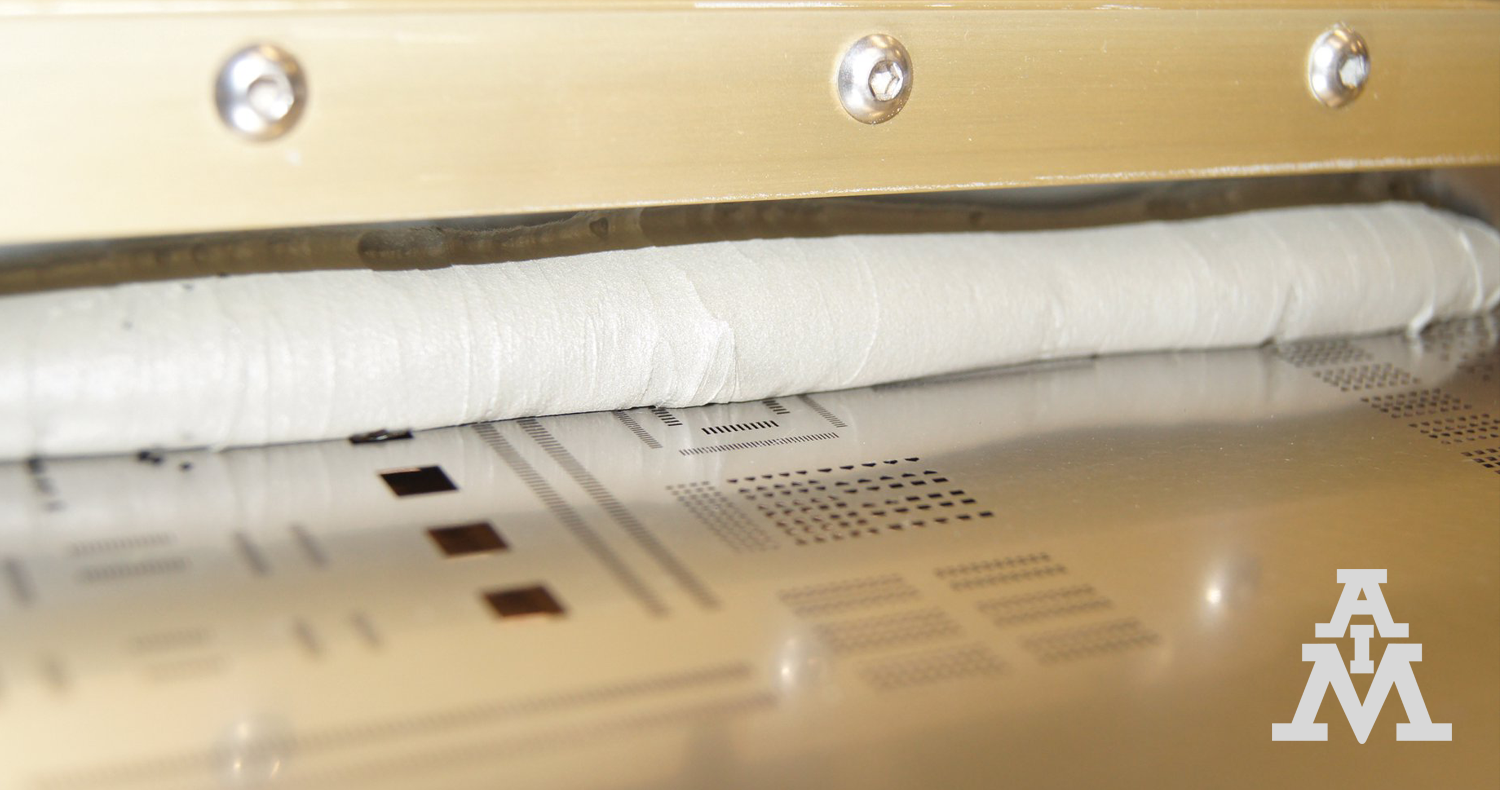

In this report, AIM’s application lab approximated a production environment in a multi-hour printing test to quantify the effect of under-stencil wipe solvent on solder paste performance. This experiment compared isopropyl alcohol (IPA) and a novel stencil cleaner. IPA is not recommended as an in-process stencil cleaner, but is often used because it is inexpensive, effective and readily available. However, IPA is not a constituent of solder pastes and can therefore cause changes to paste that will negatively impact performance.

One example of this change is that paste exposed to IPA can become...