By Tim O’Neill, Technical Marketing Manager

With RoHS exemptions set to expire, can SAC305 hang on?

It is not the strongest of the species that survive, nor the most intelligent, but the one most responsive to change.

– Charles Darwin

The final steps of RoHS will be phased in over the next 24 months and once implemented; lead will be virtually eliminated from the solder supply chain for electronic assembly. With the last exemptions applying predominantly to high reliability applications, the materials in use are being scrutinized to determine if they can perform to the mission requirements of high reliability PCB. Concurrent to this material concern, is the unrelenting trend in microelectronics; more functionality and performance in smaller spaces. As circuitry becomes denser and more power is being inserted into shrinking space, an inevitable byproduct is heat. These two realities, high reliability requirements and increased power density, are exposing deficiencies in the de facto lead free solder alloy, SAC305. SAC305 has performed adequately to this point; the processing temperatures are acceptable, it has proven sufficiently durable, and it is largely compatible with other common materials albeit at considerably higher cost than the tin lead it replaced. Typically, if an alloy other than SAC is in use, it’s for cost containment rather than solder joint reliability characteristics. But the needs of the industry are evolving based on the aforementioned changes in regulation and reliability requirements. As a result, SAC305 may fall out of favor as it has a variety of undesirable inherent characteristics.

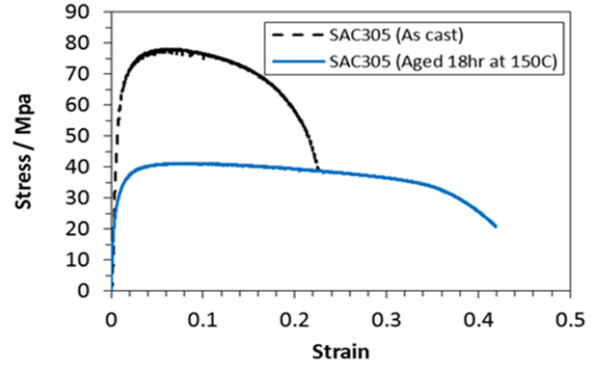

Firstly and most concerning to several high reliability user groups (including LED and automotive in particular) is the degradation of the mechanical properties of SAC305 when exposed to elevated temperatures that can lead to solder joint failure. The graphic below (Figure 1) demonstrates SAC305’s resistance to deformation under increasing tensile (pulling) stress. The black line shows the alloy in the As-Cast state, where it was tested immediately following casting. The blue line is the same test performed after the alloy sample is exposed 150°C for 18 hours. As the graph demonstrates, SAC305’s resistance to deformation drops in half with exposure to elevated temperatures.

FIGURE 1. Increasing Tensile Strain

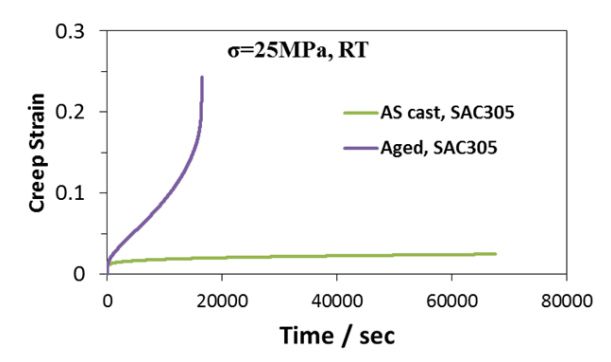

FIGURE 2. Tensile Strain Over Time

FIGURE 2 is another measure of the degradation of the mechanical performance of SAC alloy, but rather than showing degradation with increasing force, we can see the alloy is degrading with constant force over time. In this case, the “As Cast” SAC305’s resistance remains consistent where the “Aged” sample experiences a complete loss of strength in a comparatively short period of time.

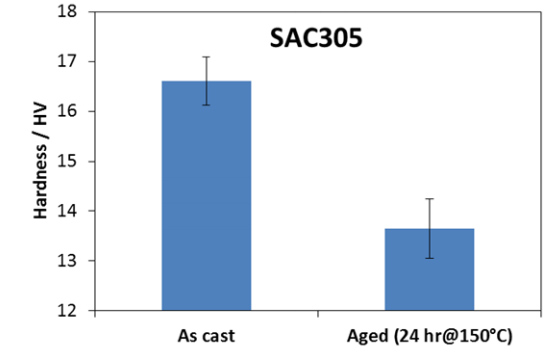

In Figure 3, the bar graph shows the “Aged” sample with a twenty percent drop in hardness when tested with a Vickers Hardness tester.

FIGURE 3. Alloy Hardness Test

These tests clearly demonstrate the loss of performance of SAC305 when exposed to high temperature.

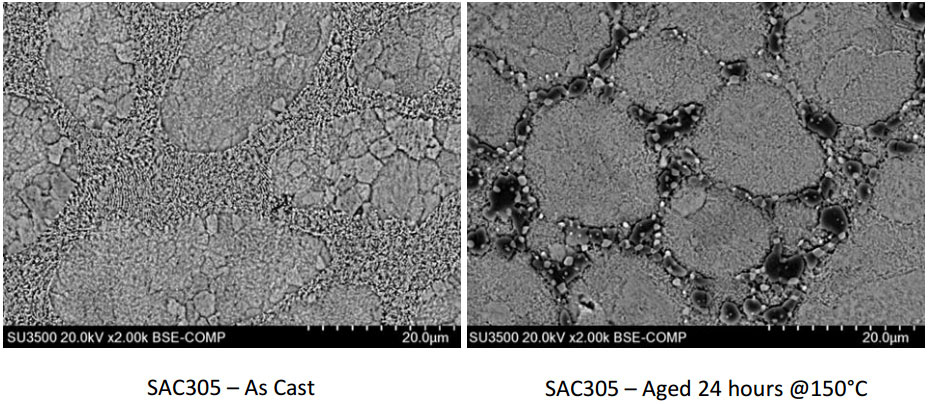

The loss of strength and durability of the alloy that is exposed to high temperature is due to a change in the microstructure of the alloy’s crystalline structure. Figure 4 compares micrographs of SAC305 alloy before and after aging. The change in the alloy’s microstructure is profound and easily observed. The dark areas in the image are coarsened precipitate of tin-silver intermetallic compounds that leads to the weakening of the alloy. New alloys have been developed using a variety of elements and micro-alloys which minimize this phenomena and create an alloy with superior thermal fatigue resistance and mechanical strength.

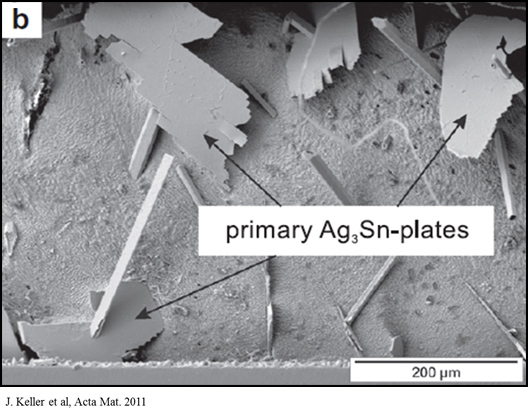

It is understood among the handheld device community that SAC305 drop shock performance is a reliability concern. SAC Alloys containing 3% or more silver are considered ”high silver” and exhibit a condition referred to silver ”platelet” formation. The solidification properties of SAC alloys are inconsistent and this allows for the development of tin/silver intermetallic structures that have different physical and mechanical properties than the surrounding alloy. Figure 5 is an interesting focused ion beam image showing these platelets in three dimensions and how drop shock cracks can propagate along the interface between a platelet and the bulk alloy.

FIGURE 4. 24 Hours @ 150˚C

FIGURE 5. >3% Silver SAC Alloys Exhibit Poor Drop Shock Performance

The simplest remedy to this condition is to reduce the silver content of the alloy, thus reducing tin/silver intermetallic. It is common to find BGAs in devices subjected to drop shock to be assembled using spheres composed of a low-silver SAC alloy to improve drop shock performance. However, reducing the silver content in the solder alloy used during assembly is more complicated as reducing the silver increases the alloy’s melting point and reduces wetting performance.

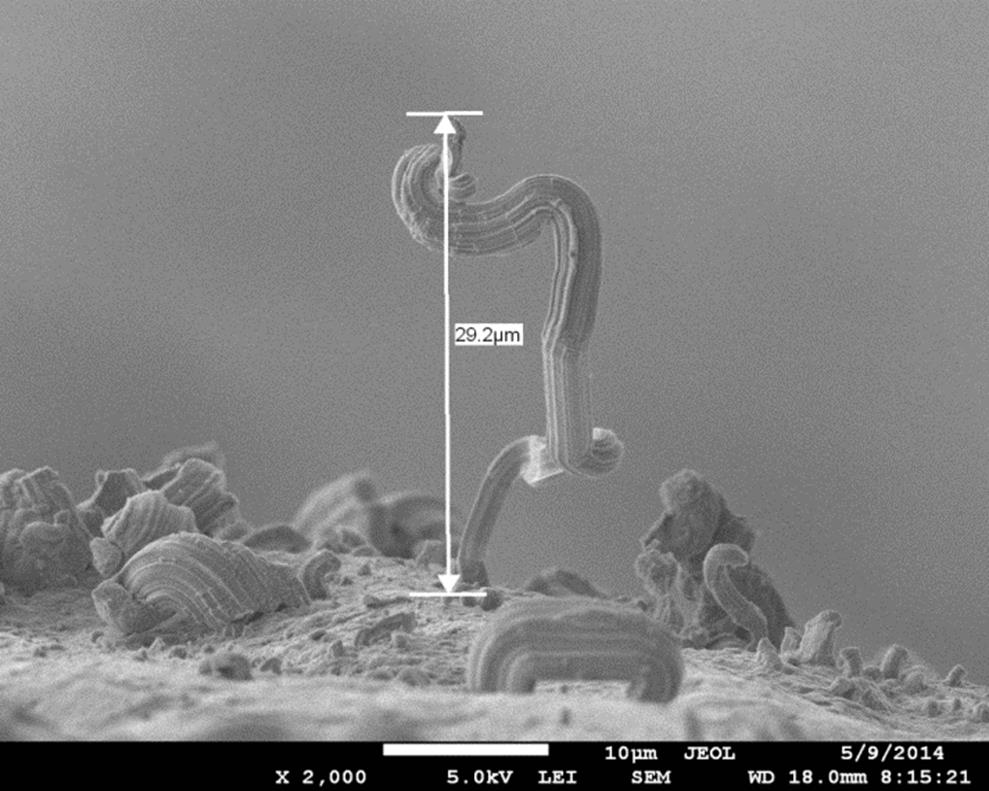

Electronics in high reliability applications are particularly concerned with tin whiskers. Tin whiskers are a stress relieving phenomenon that high tin alloys can exhibit over extended periods of time. Whiskers are ”micro-extrusions” of tin (FIGURE 6) that emanate from the surface of the solder and can result in an electrical short. The only mitigation strategy available today is conformal coating and this does not prevent the development of the whiskers, but merely is a ‘catch and contain’ strategy. While it is possible for tin whiskers to form in solder joints, they are much more likely to emanate from electroplated pure tin due to the atomic structure of the tin plating.

FIGURE 6. Tin Whisker in SAC305

New options and new understandings are emerging to meet the demands of multiple markets as RoHS exemptions expire. As discussed in our Circuits Assembly February 2017 column, we can expect applications will emerge where SAC305 is displaced by ”designer” alloys. These new alloys will provide developers and assemblers alike with new tools to meet the evolving demands of the electronics market. It is even feasible that SAC305 will be dislodged by a new de facto alloy that better serves the needs of the market place.

To improve is to change; to be perfect is to change often.

- Winston Churchill

Published in CIRCUITS ASSEMBLY

Download: