Tin, with its rich history spanning ancient civilizations to modern electronics, remains an integral metal in soldering. In this post, we explore tin’s journey—from historical significance to global market, sourcing, and processing. We’ll also delve into the increasing demand for tin, its recycling initiatives, and the push for a sustainable future.

A Brief History of Tin

Tin is a fundamental element found in the earth’s crust. A soft, silvery metal, tin is known for being nontoxic, malleable, ductile.

The discovery of tin dates back over 5,000 years ago to ancient times, where it played a vital role in shaping early cultures. One of the most significant applications was its use in the creation of bronze, an alloy formed from tin and copper. Bronze revolutionized the production of tools, weaponry, and artwork, propelling societies into a new era of craftsmanship and warfare.

Gary Todd, CC0, Wikimedia Commons

As the world progressed into the medieval period, tin remained a coveted commodity in trade networks spanning across continents. It became a key component in the construction of medieval churches, adding luster to stained glass windows and adorning grand sculptures. The iconic “tin ceiling” in architectural design became a symbol of opulence and refinement, reflecting the craftsmanship and aesthetic sensibilities of the time.

The dawn of the Industrial Revolution marked a turning point for tin as it found new applications in emerging technologies. The invention of tin cans, pioneered by Peter Durand in the early 19th century, revolutionized food preservation and distribution.

As technology accelerated in the 20th century, tin found its way into electronics manufacturing. The development of tin-lead solder alloys paved the way for mass-produced electronic devices, from radios to televisions and beyond.

The electronics revolution brought tin to the forefront of global industry. It now powers the rapid growth of the information age and shapes our digital world. Today, modern solder accounts for approximately half of all global consumption of refined tin, a proportion which is only expected to grow.

Tin in Solder: The Key Component

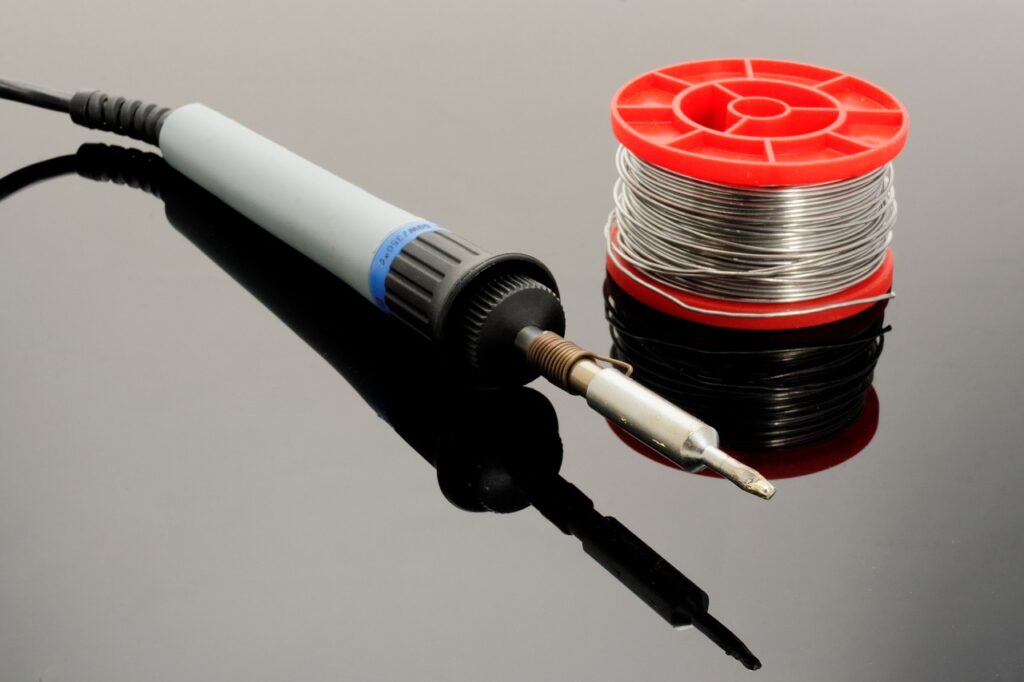

In the realm of soldering, tin reigns as the undisputed key component, underpinning the foundation of countless electrical connections. Tin’s ability to create strong and reliable bonds between components is nothing short of remarkable. It can be found in all types of solder, including bar solder, solder wire, and solder paste.

The process of soldering involves melting a metal alloy onto electronic components, allowing it to flow and form a secure bond once cooled. Tin’s low melting point makes it an ideal candidate for this task. It can fuse with other metals at relatively low temperatures which prevents damage to sensitive electronic components during the soldering process.

Tin’s excellent wetting ability also ensures it can evenly spread across metal surfaces, maximizing contact and promoting robust adhesion. This characteristic is particularly critical in modern electronics, where intricate circuitry demands precise and consistent soldering.

Tin-lead was previously the most common solder alloy due to the combination’s enhanced workability. However, concerns about lead’s toxicity resulted in a shift towards lead-free solder alloys, with tin forming the primary base.

Tin-silver-copper (SAC) alloys have since become the standard choice throughout the electronics assembly industry. The addition of silver offers excellent conductivity and mechanical strength, while copper enhances performance and is cost-effective. Modern SAC alloys – most commonly SAC305 – offer excellent solder joint reliability, thermal fatigue resistance, and a broad processing window while maintaining compliance with IPC, JEDEC, RoHS, and REACH lead-free soldering standards.

As soldering processes evolve, novel alloys will emerge. Yet one thing remains certain: tin’s role as the key component in solder will endure.

Global Market and Demand for Tin

As the world becomes increasingly connected, the demand for electronic devices only grows. Tin is essential for assembling everything from smartphones and laptops to smart home appliances and advanced medical equipment. This upsurge in electronics production has put immense pressure on the tin market.

In parallel, the rising popularity of renewable energy technologies further amplifies the demand for tin-based solders. Solar panels and wind turbines rely on tin-based solder alloys to connect photovoltaic cells and electronic components. As nations worldwide work toward reducing carbon footprints and embracing greener solutions, the demand for tin in the renewable energy sector also grows.

The intersection of these factors has propelled the demand for tin to new heights, necessitating sustainable sourcing and responsible mining practices to ensure a steady supply. Recycling initiatives have gained traction in recent years to mitigate the need for additional mining, and reduce the environmental impact associated with primary tin extraction.

Sourcing: Where Does Tin Come From?

Tin extraction primarily occurs in mines scattered around the globe. The sourcing process involves a combination of traditional mining techniques and modern exploration methods. In some regions, traditional methods, such as open-pit and underground mining, are used to extract tin ore from the Earth’s crust.

Elsewhere, modern exploration methods, including advanced geological surveys and remote sensing technologies are employed. These have revolutionized the discovery of tin deposits, leading to more efficient and targeted mining operations.

The focus on sustainable sourcing and responsible mining practices in the tin industry is increasing. Initiatives have been established to promote ethical and environmentally friendly mining practices.

From Mine to Solder: The Tin Processing Journey

The journey of tin from the depths of mines to becoming a vital soldering material is complex. The first step in the tin processing journey is the extraction of the ore from the earth. This process varies depending on the type of deposit. Methods range from traditional open-pit mining to more sophisticated underground mining techniques, as previously described. Once the ore is collected, it is transported to processing facilities for further refinement.

At the processing plant, the raw tin ore undergoes crushing and grinding to reduce it into smaller particles. The ore is then concentrated through gravity separation or flotation techniques, separating the valuable tin minerals from other rock materials. This concentration process significantly increases the tin content, making it more economically feasible for further refining.

The next crucial stage in the journey is the refining and purification of the tin concentrate to eliminate impurities. The process typically involves high-temperature smelting, where the concentrated tin is heated in furnaces to remove other elements and contaminants. This refining step ensures that the tin metal obtained is of high purity and quality, meeting the stringent standards required for modern electronic applications.

Once the refining process is complete, the purified tin metal is cast into various forms. These forms include ingots, bars, or pellets, depending on the specific requirements of the solder manufacturing industry. These different forms allow for greater flexibility in the solder production process, catering to various soldering techniques and applications.

Sustainable Practices and Tin Recycling Initiatives

In addition to responsible mining, recycling initiatives also help in alleviating the strain on tin resources and promoting a more sustainable approach. Electronic waste, such as old smartphones, laptops, and other discarded devices, contains valuable amounts of tin. Dross recycling is another crucial process for tin reclamation. Dross is a byproduct that forms during the smelting and refining processes of tin, typically comprising oxides, metallic particles, and impurities. The recycling of tin from dross involves various methods, including pyrometallurgical and hydrometallurgical processes.

AIM Solder makes it easy to recycle dross by providing customers with free reclamation buckets and shipping labels along with instructions. And once the dross is received and analyzed, customers receive credit for the recovery value of their material. As “cradle to grave” legislation is implemented, working with a metals supplier that is able to reclaim scrap metal is critical, not just for the environment, but for maintaining compliance.

Tin recycling efforts contribute to the principles of a circular economy, where materials are reused, refurbished, and recycled to minimize waste and maximize resource efficiency. By reintroducing recycled tin into the supply chain, the demand for newly mined tin is reduced, extending the life of existing resources and minimizing the pressure on natural ecosystems.

Future Trends and Prospects for Tin

Tin’s role in soldering and the global market is undeniably vital. From its ancient roots to its prominence in modern electronics, tin continues to play a crucial part in connecting our world. As the demand for electronics and renewable technologies rises, the importance of this precious metal only intensifies. Embracing sustainable practices and recycling initiatives will be essential in meeting this growing demand while preserving tin’s significance for future generations.