AIM Automotive Solutions

Zoptymalizowane i gotowe do zastosowania w przemyśle rozwiązania

Your Partner in Automotive Electronics

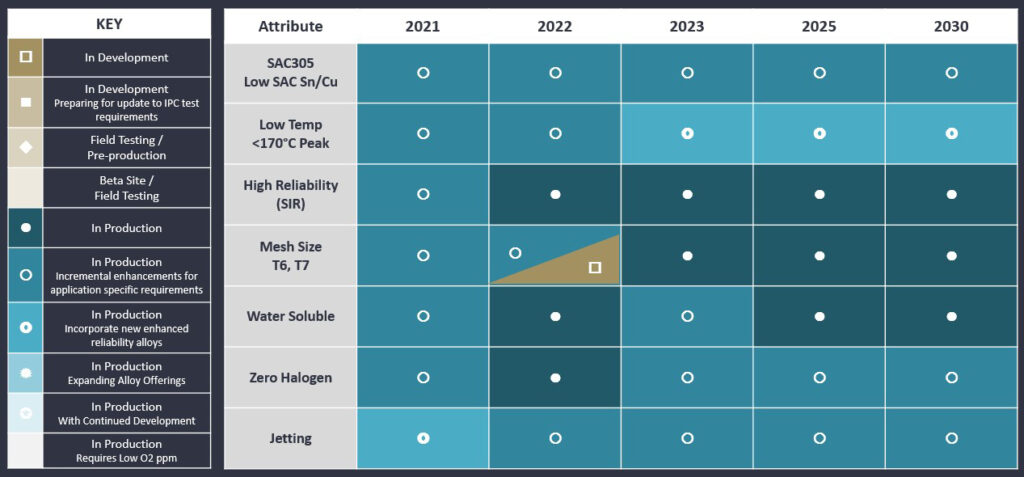

AIM Solder concentrates its research on solder paste and alloys for current and emerging requirements within the automotive industry. Collaboration with automotive OEMs and Tier 1 suppliers drives innovation in processes, materials, and supply.

AIM AUTO line of products are engineered to improve PCB reliability and extend solder joint life. AIM’s Auto line includes no clean fluxes, lead-free REL alloys in solder paste, wire and bar complying to IPC, IEC, EIN and JIS standards. AIM’s global supply chain and local engineering teams ensure automotive clients are never far from products or support.

Korzyści z Współpraca z AIM

AIM Understands Automotive Industry Challenges

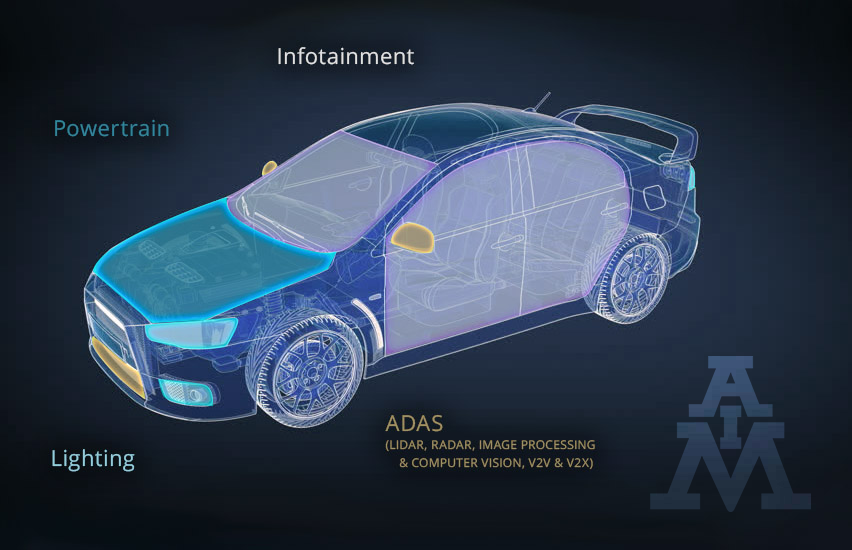

Zastosowania motoryzacyjne

The automotive industry maintains some of the strictest reliability standards. Extreme temperature changes, humidity, sunlight, and vibration are some of the demands placed on automotive electronics. AIM is an ideal partner in the high reliability automotive industry because our products are engineered to perform in harsh environments and eliminate assembly defects.

Precise Displays and Vivid Entertainment

Today’s vehicles are equipped with state-of-the-art displays that make reading your speed, switching your audio, or viewing your blind spot easier than ever. Newer displays are composed of MiniLED or MicroLED components, which require innovative soldering materials to assemble.

- AIM LUX line of products designed for LED assemblies

- NC259FPA Ultra Fine No Clean Solder Paste is engineered for ultra-fine pitch printing on high density <100-micron components

- Lead-free alloys available in micromesh powder sizes (T6, T7)

- H10 Halogen-Free No Clean Solder Paste has excellent SIR Performance eliminating dendritic growth potential

High Power, Intelligent Illumination

LEDs have proven to keep up with the durability requirements of the automotive industry while delivering intelligent, precise lighting that make your driving experience stress-free no matter the weather. AIM offers solutions that regulate heat dissipation, improve SIR performance, and increase overall solder joint reliability.

- AIM LUX line of products designed for LED assemblies

- REL61™ cost-saving alloy is proven to reduce voiding and improve mechanical reliability compared to SAC305

- V9 Low-Voiding No Clean Solder Paste results in near-zero voiding and promotes thermal dissipation

- High reliability REL22™ alloy doubles solder reliability under high thermal stress

Trwałość nawet w ekstremalnych warunkach

Whether in traffic on the highway or on an off-roading adventure, internal combustion engine (ICE) vehicles are built to endure extreme conditions. This means the electronics under the hood must perform when exposed to elevated temperature/humidity and resist vibration damage. AIM puts our products to the test to ensure mechanical and electrical reliability that weathers any storm.

- Stop REL22™ o wysokiej niezawodności oferuje lepszą odporność na cykle termiczne, wstrząsy mechaniczne i upadki/wibracje w porównaniu do SAC305

- M8 No Clean Solder Paste oferuje szerokie okno rozpływowe dla płytek drukowanych o wysokiej gęstości i mocy

- Stop REL61 posiadają silne właściwości zwilżające w porównaniu do wszystkich stopów o niskiej zawartości srebra/bez srebra

Safe and Reliable Systems

The Advanced Driver Assistance Systems (ADAS) in your vehicle respond faster than you can, preventing accidents and saving lives. These life-saving systems are only as effective as the electronics they are made of, which means the durability of the soldering materials within them must be proven in the lab and on the road. AIM’s Auto line of products are designed to keep you safe and offer improved reliability.

- H10 Halogen-Free No Clean Solder Paste leaves minimal, electrochemically safe residues in an environmentally friendly chemistry

- M8 No Clean Solder Paste exhibits excellent stencil transfer on AR<0.50

- Stop REL61 reduces tin whisker formation while reflowing at a lower peak temperature than other SAC alloys

Smart and Stress-Free Roads Ahead

Electric vehicles (EV) and their corresponding charging stations are putting new demands on circuit board assemblies. When your safety and mobility is dependent on an electric system, failure is not an option. AIM is prepared with innovative solutions that meet the emerging and future requirements of the EV market.

- H10 Halogen-Free No Clean Solder Paste offers superior SIR performance in an environmentally friendly formulation

- AIM REL22™ to wysoka niezawodność/wysoka wytrzymałość porównywalna do stopów Sn/Ag/Bi/Sb/Ni/Cu z szerszym zakresem procesu montażu

- M8 No Clean Solder Paste exhibits excellent stencil transfer even on AR <0.50