AIM LED/MiniLED & Display Solutions

Optimized & Industry-ready Solutions

Your Partner in LED Electronics

AIM Solder is committed to offering high-quality solder alloys and flux chemistries for the LED, miniLED, high power LED and novel microLED industries. Our partnerships with global leaders in assembly technology and manufacturing help AIM develop solutions for the rapidly expanding LED lighting and display market. Read more to learn about our LUX line of products designed to solve your LED assembly challenges.

AIM offers solutions for LED applications including automotive, commercial lighting, and innovative display technologies. As one of the world’s largest suppliers of Type 6 solder paste, AIM has the experience to provide process development guidance combined with innovative product offerings to miniLED display assemblers.

AIM’s LUX line of products, REL alloys, silver-free, and void-free solder pastes combined with Type 6 alloy powders are formulated to improve existing LED technologies and address future needs.

Benefits of Partnering with AIM

AIM Understands LED Industry Challenges

LED & Display Applications

The advent of ultra-miniature LED technology is revolutionizing component assembly, demanding a reimagining of traditional SMT techniques. AIM, at the forefront of this transformation, collaborates with industry partners to develop cutting-edge materials and practices for miniLED assembly. The key challenge lies in the scale, with tens of thousands of tiny components requiring precise placement and reflow on a single display panel at rapid production speeds.

The advent of ultra-miniature LED technology is revolutionizing component assembly, demanding a reimagining of traditional SMT techniques. AIM, at the forefront of this transformation, collaborates with industry partners to develop cutting-edge materials and practices for miniLED assembly. The key challenge lies in the scale, with tens of thousands of tiny components requiring precise placement and reflow on a single display panel at rapid production speeds.

Revolutionizing LED Assembly with AIM Innovation

- AIM LUX line: Products specifically designed for LED assemblies

- NC259FPA No Clean Solder Paste: Engineered for ultra-fine pitch printing on high-density <100-micron components

- Lead-free alloys: Available in micromesh powder sizes (T6, T7)

- H10 Halogen-Free No Clean Solder Paste: Excellent SIR performance eliminating dendritic growth potential

Major competitors in the display market today fit into two categories: OLED and LCD. The main difference between OLED and LCD components is that OLED pixels illuminate independently while LCDs illuminate using a direct LED backlight. The backlight of LCDs causes the blackest blacks to still appear greyish, while OLED pixels shut off completely. AIM’s R&D understands the challenges faced in the field, which helps keep us on the cutting-edge of product development.

Elevating Displays: From OLED to Mini and Micro LEDs

- Local Dimming Innovation: Achieving superior contrast in LCDs with Mini LED and local dimming zones

- Micro LED Advantages: Inorganic compounds, lower power consumption, and no burn-in risk

- AIM’s LUX Line: Cutting-edge products for LED assembly, establishing global leadership in T6 solder paste supply.

The automotive industry maintains some of the strictest reliability standards since their products are exposed to extreme temperature changes, humidity, sunlight, and vibration. AIM is an ideal partner in the high reliability and automotive lighting industry. Our products have been developed to perform in harsh environments and our technical support engineers are prepared to solve the challenges posed by LED, miniLED and microLED implementation in high reliability and automotive assemblies.

High Power and Harsh Operating Environments

- AIM’s REL22™ solder alloy combined with our advanced flux formulations more than double thermal cycling performance for longer LED lifespan

- Low voiding pastes and alloys improve thermal dissipation on BTC LED packages

- REACH and RoHS compliant formulas ensure worldwide environmental compliance

- 1000+ hour electrochemical testing reduces risk of electrical failures

- Passes HTOL testing

AIM offers high-quality and energy efficient solutions for industrial and commercial LED applications. Our formulations are designed for use in high performance environments and aid in thermal management of high-power LED components. AIM also offers reduced/low temperature soldering solutions which helps reduce component warpage during reflow.

High Yield Low-Cost Lighting Products

- High reliability, SAC, and silver-free alloy options

- AIM’s REL22™ Solder Alloy combined with our advanced flux formulations double thermal cycling performance for longer LED lifespan

- A drop-in for SAC305 processes, AIM’s REL61™ Solder Alloy dramatically reduces cost with no loss of production yields or product reliability

- AIM’s NC273LT Low Temperature Solder Paste or <170°C reflow temperature

- Low voiding solder paste and alloys improve thermal dissipation on BTC LED packaging

- REACH and RoHS compliant formulas ensure worldwide environmental compliance

- 1000+ hour electrochemical testing reduces risk of electrical failures

- Passes HTOL testing

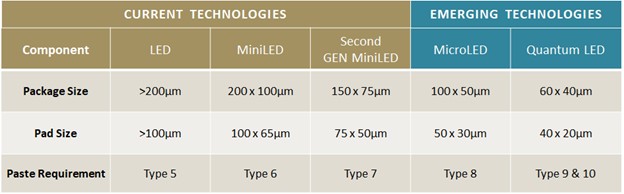

AIM LED Technology Roadmap

Recommended AIM Products for LED and Display Applications

- 2.5X increased thermal cycling performance compared to SAC alloys

- Voiding <5% for improved thermal management

- Outperforms first generation high reliability alloys

- Available in bar, solder wire & solder paste

- Low silver, cost saving alloy

- Reduces void formation preventing LED overheating

- Passes LED HTOL testing

- Available in bar, solder wire & solder paste

- Silver-free

- Widely accepted replacement for SAC alloys

- Available in bar, solder wire & solder paste

- T6 and finer powders available

- Precise print definition and high print transfer efficiencies

- Nitrogen reflow compatible

- Improves wetting

- High shear strength solder joints

- High tack force

- T6 and finer powders compatible

- High print transfer efficiencies for 01005 and low area ratio components

- <5% voiding reduces LED overheating

- Minimal, transparent residue on white substrates

- 8+ hour stencil life