Von Timothy O'Neill und Karl Seelig

Der Begriff "Squircle" ist eine Wortschöpfung aus "Quadrat" und "Kreis". Er sieht aus wie ein Quadrat mit abgerundeten Ecken. Mathematisch gesehen ist diese Form als Superellipse bekannt. Bei der Gestaltung von SMT-Schablonen wird oft eine lockerere Definition verwendet, und die tatsächliche Form wird als abgerundetes Quadrat bezeichnet - sie entsteht, indem man vier Quadranten eines Kreises trennt und sie mit einer geraden Linie verbindet.

Wie sich herausstellte, ist der Squircle eine effektive Form zur Maximierung des Lotpastenvolumens auf engem Raum und zur Verbesserung der Übertragungseffizienz.

Die Eigenschaften von Rechtecköffnungen

Das Squircle-Design vereint die positiven Eigenschaften von kreisförmigen und quadratischen Öffnungen.

Merkmale der Kreisblende

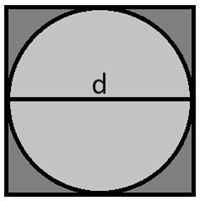

Aufgrund ihres glatten, abgerundeten Designs haben kreisförmige Öffnungen keine Pad-überlappenden Ecken und keine toten Pastenbereiche. Es ist jedoch viel schwieriger, mit Kreisen ein ausreichendes Pastenvolumen auf engem Raum zu erreichen. Das liegt daran, dass die Fläche eines Kreises mit einem bestimmten Durchmesser kleiner ist als die eines Quadrats mit der gleichen Seitenlänge (mit den Formeln für die Fläche eines Kreises im Vergleich zur Fläche eines Quadrats: (π/4)d2 < d2).

Außerdem haben Kreise über den gesamten Durchmesser der Öffnung die gleiche Oberflächenspannung. Beim Trennen kann dies die Menge an Lotpaste erhöhen, die in der Öffnung verbleibt. Stellen Sie sich eine Seifenblase auf einer flachen Oberfläche vor; die gleiche Oberflächenspannung hält sie stabil. Die gleiche Eigenschaft hält die Paste davon ab, aus der kreisförmigen Öffnung auszutreten.

Quadratische Blende Merkmale

Ein Quadrat hat den Vorteil, dass das Pastenvolumen in engen Räumen maximiert wird. Beim Drucken von Lotpaste neigen die Partikel jedoch dazu, sich in den scharfen Öffnungsecken zu verklumpen, was zu größeren Abweichungen von Ablagerung zu Ablagerung führt. Es ist auch wahrscheinlich, dass diese Abweichung mit der Zeit zunimmt, wenn die Wischwirkung der Schablone nachlässt und die Pastenansammlung zunimmt.

Quadrate haben von Natur aus eine größere Oberfläche als Kreise mit denselben Hauptabmessungen, so dass sie mehr Paste ablagern sollten. Wenn jedoch die Ecken, an denen die Paste hängen bleibt, die Padkanten überlappen, entstehen Dichtungsprobleme, die die Schwankungsbreite weiter erhöhen können.

Blenden-Eckige Blenden

Der Squircle kombiniert die volumetrischen Vorteile quadratischer Öffnungen mit den Vorteilen abgerundeter Formen bei der Pastenabgabe, wodurch auch Bereiche mit Pastenansammlungen vermieden werden. Er bietet das Beste aus beiden Welten für einen äußerst anspruchsvollen Teil des Druckprozesses.

Experimenteller Vergleich von Blendenformen

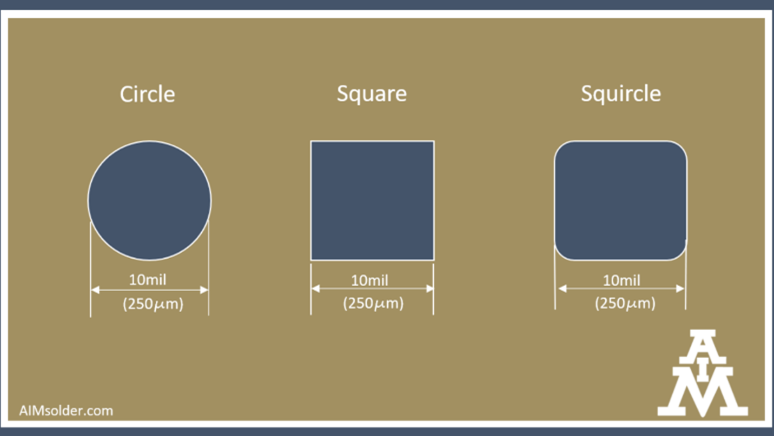

Ausführliche Drucktests im Anwendungslabor von AIM in Juarez, Mexiko, mit einer Schablone, die quadratische, kreisförmige und kreisförmige Blendenformen enthielt, untermauern die überzeugenden Argumente für den Squircle als Lösung für viele Druckprobleme. Durch die Prüfung von Öffnungen mit denselben Hauptabmessungen (Durchmesser oder Seitenlänge) und ähnlichen Flächenverhältnissen konnten wir die Übertragungseffizienz und das tatsächliche Ablagerungsvolumen direkt vergleichen.

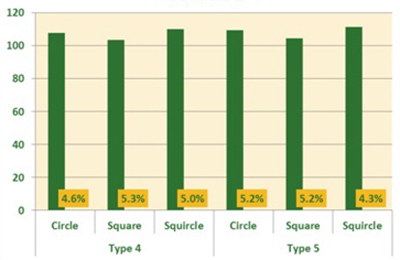

ABBILDUNG 4 zeigt die gemessenen Übertragungswirkungsgrade und die berechneten Variationskoeffizienten der einzelnen Blendentypen. Beachten Sie, dass die Übertragungseffizienz beim Quadrat etwas geringer ist als beim Kreis, allerdings nur um wenige Prozentpunkte. Das Quadrat hat auch eine etwas höhere Variation mit der Paste Typ 4 und entspricht den Daten der Paste Typ 5. Der Kreis hat durchweg die höchste Übertragungsrate und eine vergleichbare oder geringere Abweichung als die Quadrate oder Kreise.

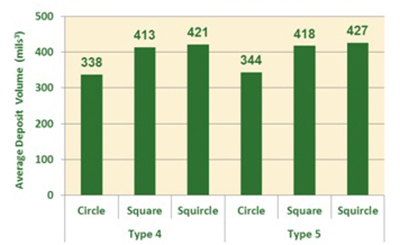

ABBILDUNG 5 zeigt das durchschnittliche Ablagerungsvolumen der einzelnen Blendenformen. Man beachte, dass das Quadrat zwar eine geringere Übertragungseffizienz aufweist, seine größere Fläche aber zu höheren Volumina führt als der Kreis. Die höchste Ablagerungsmenge aller Öffnungen wurde jedoch mit dem Kreis erzielt. In allen Fällen lieferte die Paste vom Typ 5 durchweg geringfügig höhere Volumina, aber nicht genug, um einen Übergang zu dieser Paste in einer Produktionsumgebung zu rechtfertigen, in der Kosten, separate Lagerung und Reflow-Probleme auftreten würden.

Abschließende Anmerkungen

Es ist wichtig anzumerken, dass bei diesen Experimenten die Übertragungsraten sehr hoch und die Variationsraten sehr niedrig sind, verglichen mit typischen Ergebnissen aus ähnlichen Drucktests. Diese Drucktests wurden unter idealen Bedingungen mit einer nanobeschichteten Polymerschablone durchgeführt. Es ist davon auszugehen, dass in Produktionsumgebungen ähnliche Trends zu erwarten sind, allerdings mit niedrigeren Übertragungsraten und höheren Schwankungsbreiten. Es ist auch sinnvoll, die Verwendung von Nanobeschichtungen auf Schablonen mit engen Flächenverhältnissen in Betracht zu ziehen, da sie (häufig dokumentierte) Qualitätsverbesserungen bieten.

Die gesammelten, aber hier nicht gezeigten Daten deuten auch darauf hin, dass der Squircle robuster gegenüber den Auswirkungen der Alterung bei Raumtemperatur und langen Druckpausen (>60 min.) ist.

Auch wenn unsere Studie das Potenzial des Squircles unterstreicht, sind weitere Forschungen erforderlich, um seine Einsatzmöglichkeiten bei verschiedenen Montagebedingungen und Materialien zu untersuchen. Nichtsdestotrotz sind die ersten Ergebnisse vielversprechend und positionieren Squircles als eine praktikable Erweiterung der Schablonendesignverfahren.

Basierend auf dem Artikel "Die Quadratur des Kreises", der ursprünglich in circuits assembly veröffentlicht wurde.