AIM Solid and Cored Solder Wire

Optimized & Industry-ready Solutions

AIM Solder Wire

AIM’s complete line of solid and cored solder wire is available in a wide selection of alloys including AIM’s innovative REL alloys, lead-free and leaded solder alloys. AIM’s cored solder wire is available with no clean, water soluble and rosin flux chemistries. The combination of available alloys and novel flux chemistries offer superior soldering performance across a variety of applications, making AIM the industry’s premier solder wire manufacturer. AIM solder wire is REACH and RoHS compliant and tested to meet or exceed IPC J-STD-006 and J-STD-001 requirements.

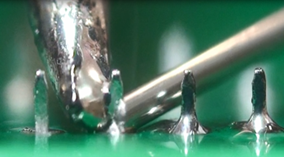

AIM’s proprietary production methods ensure a void-free wire and consistent performance. AIM’s hand and robotic solder wires have been engineered for powerful wetting, fast thermal transfer, and high reliability across a wide range of through-hole and SMT applications. AIM solder wire is suitable for all electronic applications including consumer, automotive, LED, military and medical industries.

AIM’s no clean cored solder wire provides excellent wetting properties combined with a wide process window, as well as superior solder penetration into plated through holes with minimal, clear residues. AIM’s no clean solder wire offerings are REACH and RoHS compliant, halogen-free and pass J-STD-004A/B and JIS AA requirements.

AIM’s water soluble cored solder wire’s activator system offers rapid oxide removal resulting in faster wetting and maximum capillary action. Water soluble cored solder wire residues can be easily removed using heated DI water alone.

AIM’s rosin based cored solder wire is designed for use where high activity flux is required. AIM’s rosin mildly activated (RMA) and rosin activated (RA) cored solder wire provides powerful performance on oxidized or uncleaned surfaces with excellent thermal transfer and wetting properties.

AIM’s cored solder wire for robotic soldering is engineered to promote fast thermal transfer and extend solder tip life. AIM’s solders allow high feed rates for point-to-point and drag soldering with excellent barrel fill. Post solder residue is minimal, clear and passes J-STD-004A/B and JIS AA requirements. Specialized spooling minimizes jams and drifting.

AIM’s cored solder wire for hand soldering is operator friendly, producing low odor and smoke. AIM’s solder wire is engineered to promote thermal transfer and fast wetting, eliminating the need to use additional flux.

Solder Wire Selection Guide:

| Product | Flux Type | Standard Alloys | Product Attributes |

|---|---|---|---|

| RX18 | No Clean | REL22™, REL61™, SAC Alloys, SN100C, Sn/Pb Alloys, Sn/Cu Alloys | Engineered for robotic soldering | No voids – no skips | Fast wetting and feed rates | Extends solder tip life | Rapid solder penetration on through hole components |

| CX18 | No Clean | REL22™, REL61™, SAC Alloys, SN100C, Sn/Pb Alloys, Sn/Cu Alloys | Fast wetting | Minimal and clear residue | Extends solder tip life | Low odor/fumes |

| OAJ | Water Soluble | SAC Alloys, Sn/Pb Alloys | High flux activity level | Excellent wetting | Reduces oxidation of solder iron tip | Remove residues with DI water |

| WS482 | Water Soluble | SAC Alloys, SN100C | Halide-free | Excellent wetting and thermal transfer | High flux activity level |

| RMA | Rosin | Sn/Pb Alloys | Promotes thermal transfer | ROL0 per J-STD-004B | Glycol-free | Fast wetting properties |

| GlowCore | No Clean | Pb Alloys | Engineered for hand soldering applications | Clear Residue | Extends Solder Tip Life | ROL0 per IPC J-Std-004 |

| LV05 | No Clean | SAC305 | Optimized for Robotic Soldering | Excellent Wetting Properties | Excellent Thermal Transfer | REACH and RoHS Compliant | ROL1 per Current J-STD-004 |