AIM Solder Paste

Optimized & Industry-ready Solutions

AIM Solder Paste

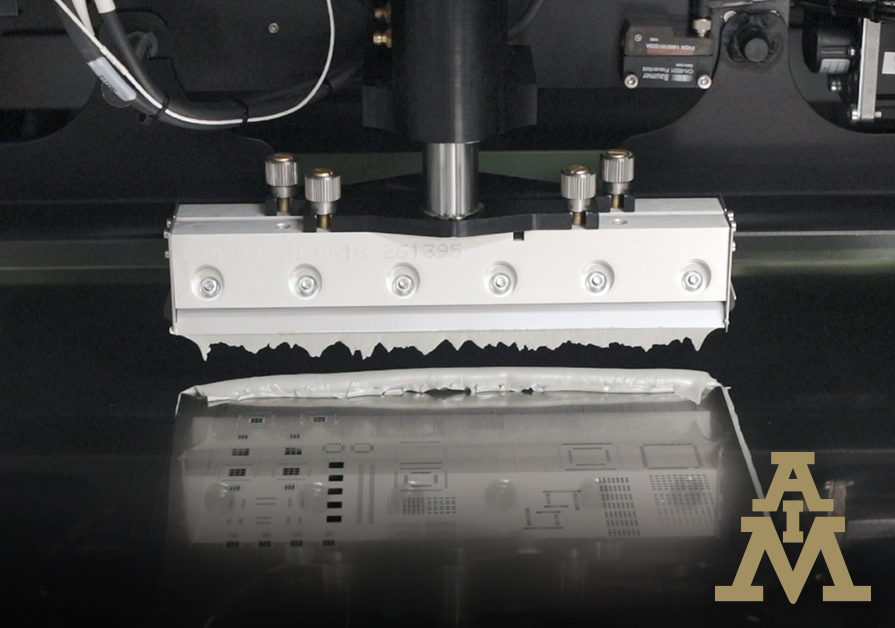

AIM’s complete line of solder paste has been developed to deliver robust performance, ease of use and cost effectiveness. AIM solder pastes resolve difficult issues including QFN voiding, low area ratio printing, and high reliability requirements for consumer, LED, automotive, aerospace and military applications.

AIM solder paste is available in no clean, water soluble, and RMA formulations with a wide variety of alloy powder sizes and offerings including AIM’s proven REL alloys, SAC, SN100C® and lead-based solders. AIM’s alloy and flux combinations provide high quality performance for a wide variety of SMT applications. In addition to SAC based SMT paste, AIM offers low temperature solder paste and jetting solder paste.

AIM’s no clean solder paste combines performance and reliability without the expense of cleaning. Designed to provide stable transfer efficiencies, powerful wetting, and low voiding, AIM no clean solder pastes address current and future assembly challenges. AIM’s full line of no clean solder paste is available in a wide selection of alloys to meet your process requirements. AIM has partnered with industry cleaner and chemistry manufacturers to ensure residue can be removed when necessary.

AIM’s water soluble solder paste products have been engineered for powerful wetting and exceptional print performance even in high humidity environments. AIM water soluble paste residues are easily removed with DI water alone up to 48 hours after reflow, even under low stand-off devices. AIM’s formulations provide a low foaming solder paste that can extend closed loop filtration service life. AIM’s water soluble product offerings exceed industry demands for a reliable, low voiding solder paste.

AIM’s RMA/RA solder pastes are designed for use where mil spec performance is required. AIM rosin based solder pastes provide modern paste print performance combined with traditional military compliance. Additionally, AIM’s RMA/RA solder pastes can withstand extended hot reflow profiles required for backplane and thermally massive assemblies. AIM’s rosin solder pastes provide superior performance on oxidized or uncleaned surfaces and long pause-to-print capabilities. AIM has partnered with aqueous, solvent and vapor degreaser cleaning manufacturers to ensure residues can be removed with all systems and leave no white residue.

AIM’s low temperature solder paste offers exceptional performance combined with peak reflow temperatures as low as 170°C. AIM’s NC273LT solder paste provides 8+ hour stencil life, stable transfer efficiency and excellent wetting, while eliminating solder balling that is common with bismuth bearing pastes.

Solder Paste Selection Guide:

| Product | Flux Type | Available Powder Sizes* | Standard Alloys* | Dispensing Capability | Product Attributes |

|---|---|---|---|---|---|

| NC273LT | No Clean | T4 | Sn/Bi Alloys | ✓ Yes | Used for low or reduced temperature applications | Improved wetting for use with bismuth alloys | 8+ hour stencil life |

| M8 | No Clean | T4 - T6 | REL22™, REL61™, SAC Alloys, SN100C, Sn/Pb Alloys, Sn/Cu Alloys | ✓ Yes | Low voiding | Fine pitch printing | Mitigates print defects (HiP) | Minimal, transparent, and easy to clean residues |

| J8 | No Clean | T6 | SAC Alloys, Sn/Pb Alloys | ✓ Jetting | Low voiding | No skips | Capable of 200μm deposits |

| NC257MD | No Clean | T5 | SAC305, Sn63/Pb37 | ✓ Jetting | For use in Mycronic Jet Printers | Prolongs ejector life | Reduces voiding |

| NC259FPA | No Clean | T6 and finer | SAC305, SN100C | No | Precise print definition with Type 6 and smaller alloy powder | Clear flux residue | Nitrogen reflow recommended | Zero halogen |

| W20 | Water Soluble | T4, T5 | SAC305 | No | Halogen/Halide Free | Residue easily cleaned in DI Water | 8+ hour stencil life | 2+ week extended cleaning window |

| WS488 | Water Soluble | T4 | SAC Alloys, Sn/Pb Alloys | ✓ Yes | Excellent wetting | Residue easily cleaned in DI water | Superior slump resistance | 8+ hour stencil life |

| RMA258-15R | Rosin | T4 | SAC Alloys, Sn/Pb Alloys | ✓ Yes | Long pause-to-print capabilities | Reduced voiding | For use during long, hot reflow profiles |

| V9 | No Clean | T4 | SAC305 | No | Low-Voiding | Consistent Printing with Area Ratio <0.66 | High Reliability (SIR) | REACH and RoHS Compliant |

| H10 | No Clean | T4, T5 | SAC305, REL22™, REL61™ | No | Zero Halogen/Halide | High Reliability | Low Voiding | Print Capability to 0.50AR with T4 |

*Additional powder sizes may be available upon request.

Solder Powder Size Quick Guide:

AIM Solder Pastes come in different powder sizes, ranging from Type 3 to Type 7.

| Type | Size (µm) | Lower Limit of Stencil Aperture* | Use Cases |

|---|---|---|---|

| Type 3 | 25-45 µm | 225 µm | 0402s and larger |

| Type 4 | 20-38 µm | 190 µm | Industry standard; 0201s, 0.5mm BGAs |

| Type 5 | 15-25 µm | 125 µm | µBGAs, 01005s |

| Type 6 | 5-15 µm | 75 µm | MicroLEDs, advanced SiP |

| Type 7 | 2-11 µm | 55 µm | Micro/nano devices |

*Per 5-ball rule